Sodium-Ion EV Batteries: A Game-Changer for Electric Vehicles

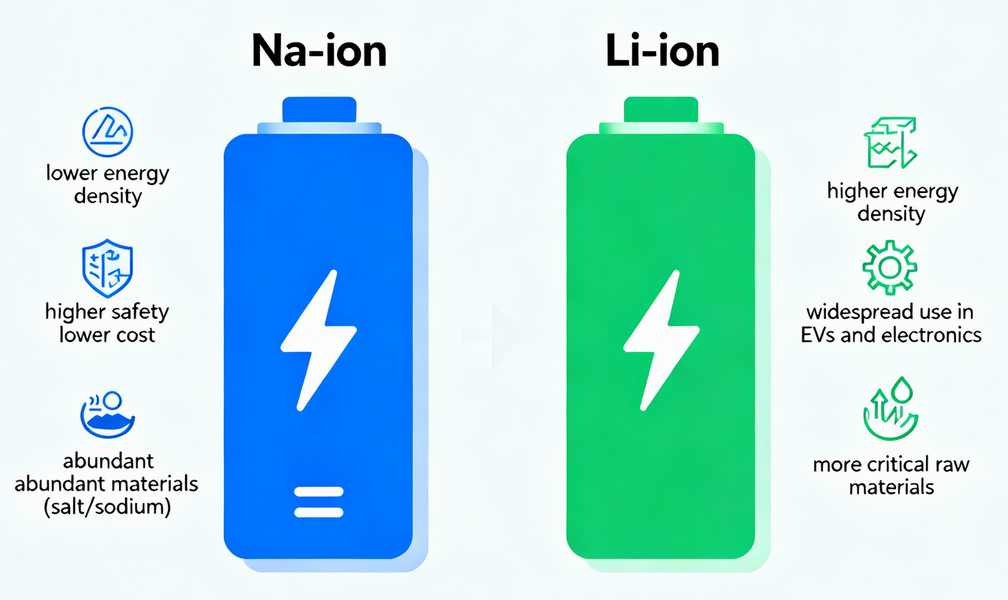

The electric vehicle (EV) industry is transforming. For years, lithium-ion batteries dominated the market, powering most EVs. However, sodium-ion EV batteries have rapidly advanced. They are now a serious and viable option for electric vehicles. This shift comes from major performance breakthroughs, significant cost reductions, and impressive scalability. Consequently, sodium-ion technology is set to redefine affordable and sustainable EVs.

Two key developments drive this transition. Firstly, CATL, a leading battery company, began commercial production of its Naxtra sodium-ion cells. Secondly, Zhaona New Energy revealed a high-density solid-state sodium-ion prototype. These milestones confirm the feasibility of sodium-ion batteries. Furthermore, they establish them as a powerful, cost-effective, and eco-friendly alternative to lithium. This promises to speed up global EV adoption.

Enhanced Performance: Breaking the Energy Density Barrier for EV Batteries

Energy density was a major hurdle for sodium-ion EV batteries. This metric directly impacts an EV’s driving range. However, recent innovations have overcome this challenge. Now, sodium-ion technology competes directly with lithium. For example, CATL’s Naxtra sodium-ion cells achieved an impressive 175 Wh per kilogram.

This performance is significant. It surpasses many existing lithium iron phosphate (LFP) batteries, which usually range from 160 to 170 Wh per kilogram. With this high energy density, EVs using Naxtra cells can reach up to 500 kilometers on a single charge. Consequently, sodium-ion batteries can power mainstream full-size electric vehicles. They meet various consumer needs, from daily commutes to long trips, challenging lithium’s dominance.

Furthermore, Zhaona New Energy announced another breakthrough. In December, they revealed a solid-state sodium-ion battery with an astounding 348.5 Wh per kilogram. This advanced design uses a ceramic-coated structure and removes the anode. This boosts energy density and improves stability and safety. Therefore, this performance significantly narrows the gap with high-end nickel manganese cobalt (NMC) lithium batteries, found in premium EVs.

Cost-Effective & Safe: Key Benefits of Sodium-Ion EV Batteries

Sodium-ion EV batteries offer several powerful advantages beyond energy density. These benefits make them highly attractive for mass-producing electric vehicles. They include:

- Significantly lower manufacturing costs

- Superior cold-weather performance

- Improved safety during transport and operation

Sodium is abundant on Earth, easily found in sources like sea salt. This makes it much cheaper than scarce lithium. Furthermore, sodium-ion technology avoids expensive and controversial materials such as cobalt and nickel. These batteries also use affordable aluminum instead of copper in current collectors, cutting production costs further.

Industry experts predict sodium-ion EV battery cell costs could drop to around $40 per kilowatt-hour. This is a huge reduction from current LFP battery costs, which are about $70 per kilowatt-hour. Achieving this price point is transformative. It allows for commercially viable EVs priced near $20,000 without government subsidies. Consequently, electric mobility becomes truly accessible globally.

Enhanced Cold-Weather Performance

Lithium-ion batteries often struggle in cold weather, leading to reduced range and inefficient charging. However, sodium-ion batteries perform exceptionally well in low temperatures. For instance, CATL’s Naxtra cells maintain about 90% capacity even at -40 degrees Celsius. This capability directly solves a major lithium weakness, making sodium-ion batteries ideal for EVs in diverse climates.

Superior Safety Features

Safety is another crucial advantage for sodium-ion batteries. Unlike lithium-ion types, which need a minimum charge to prevent short circuits and thermal runaway, sodium-ion batteries can discharge to zero volts safely. This “zero-voltage tolerance” greatly improves storage and shipping safety. It also simplifies logistics and reduces risks. The ability to fully discharge and store these batteries without damage or increased risk offers significant operational and cost savings.

Hybrid Battery Systems: A Balanced Approach for EV Power

Battery manufacturers are not entirely replacing lithium-ion technology. Instead, they are exploring advanced mixed-chemistry designs, known as hybrid battery systems. In these systems, sodium-ion EV batteries are strategically integrated. They leverage their unique strengths, including:

- Superior cold-weather performance

- Rapid charge and discharge capabilities

- Inherent cost efficiency

Simultaneously, lithium-ion cells still provide high energy density. This is crucial for extended driving ranges and high-performance applications. This intelligent, complementary approach gives automakers flexibility. They can fine-tune battery performance for specific needs, climates, and EV usage.

For example, an urban EV in a cold climate might use a sodium-ion dominant pack. This ensures optimal cold-weather reliability and cost savings. In contrast, a long-range luxury EV might integrate lithium-ion cells for peak energy density. While large-scale deployment is still new, rapid development suggests a future of coexisting technologies. This creates optimized and adaptable energy storage solutions for a diverse EV market.

Global Expansion: Scalability & Sustainability of Sodium-Ion EV Batteries

The global manufacturing of sodium-ion EV batteries is rapidly expanding. China leads this industrial revolution. Major companies like CATL, BYD, and HiNa Battery are investing heavily to boost production. BYD’s facility in Qinghai, for example, already produces sodium-ion cells for entry-level EVs. This shows a clear path to commercial success and widespread use.

Beyond China, countries worldwide recognize sodium-ion technology’s strategic importance. India, for instance, is increasing investment through Reliance and KPIT. Their focus is on integrating sodium-ion batteries into three-wheelers and light commercial vehicles. These are crucial for sustainable urban mobility. In Europe, TIAMAT develops fast-charging sodium-ion cells. Similarly, in the United States, Natron Energy pioneers sodium-ion use for grid-scale energy storage.

Sodium’s widespread availability significantly reduces global reliance on lithium imports. Lithium often involves geopolitical issues and supply chain risks. Moreover, sodium-ion battery design eliminates the need for cobalt and nickel mining. These industries frequently cause environmental damage and ethical concerns. Furthermore, these batteries are easier and cheaper to recycle. This aligns with strict sustainability standards in Europe and promotes a circular economy. This global effort promises not only tech advancement but also national energy self-reliance and environmental care.

A Diverse Future: The Impact of Sodium-Ion EV Batteries on Electric Mobility

Lithium-ion batteries will likely remain dominant for high-performance uses, like sports cars and heavy-duty trucks. Here, minimal weight and maximum energy density are critical. However, the rise of sodium-ion EV batteries marks a major shift for the wider electric vehicle market. Their compelling features include lower costs, enhanced safety, superior cold-weather performance, and sustainable materials. Consequently, sodium-ion batteries are now a strong and viable option for most consumer electric vehicles.

This strategic mix of battery chemistries promises a more robust and adaptable future for electric mobility. It will lessen global dependence on single supply chains and reduce market volatility. Most importantly, it will accelerate the global shift to cleaner transportation. The emergence of sodium-ion batteries is a technological triumph. It highlights the innovation driving the electric revolution, creating a more accessible and sustainable EV future for everyone.