Revolutionizing Electric Vehicles with Sodium-Ion Batteries

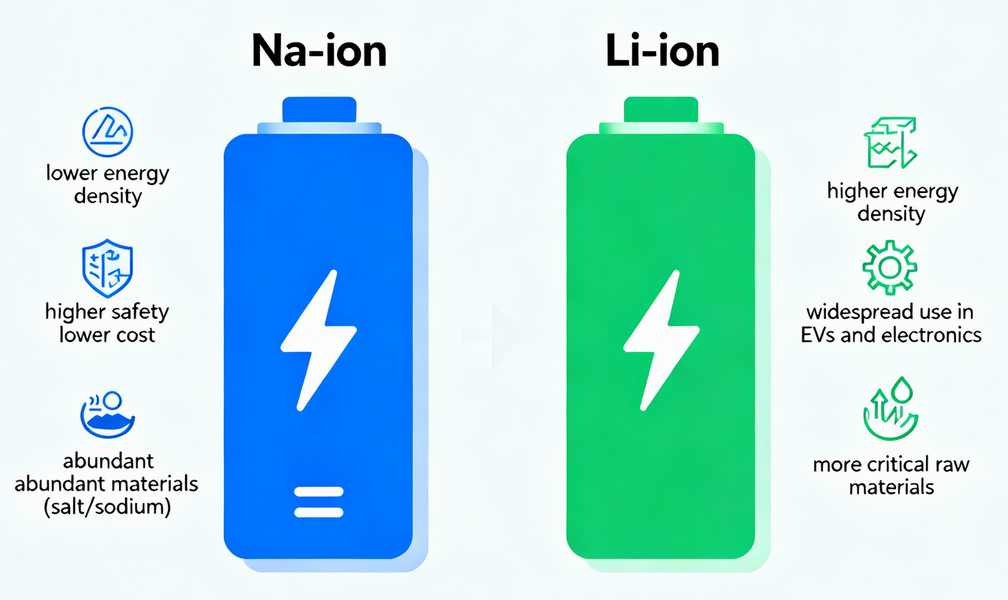

The landscape of electric vehicle (EV) battery technology is undergoing a significant transformation. For many years, lithium-ion batteries have dominated the market. However, a new contender, sodium-ion EV batteries, has rapidly emerged as a serious and viable option for EVs. Recent breakthroughs in performance, cost-effectiveness, and scalability have propelled this technology from a niche alternative to a mainstream solution, promising to revolutionize the affordability and sustainability of electric transportation.

This shift is largely attributed to groundbreaking developments. For example, CATL’s commercial production of its Naxtra sodium-ion cells marks a major milestone. Furthermore, Zhaona New Energy has unveiled a high-density solid-state sodium-ion prototype. These advancements collectively position sodium-ion batteries as a compelling alternative, challenging lithium’s long-held dominance and fostering a more diverse and resilient EV ecosystem.

Breaking the Energy Density Barrier for Sodium-Ion EV Batteries

Historically, energy density has been a primary hurdle for sodium-ion batteries, impacting EV range. Nevertheless, this barrier is rapidly being overcome. CATL’s Naxtra sodium-ion EV batteries, which recently entered mass production, boast an impressive energy density of 175 Wh per kilogram. This figure represents a substantial improvement for sodium-ion technology. Moreover, it places it in direct competition with many lithium iron phosphate (LFP) batteries, which typically offer 160-170 Wh per kilogram.

Such advancements mean that full-size electric vehicles powered by these new sodium-ion cells can achieve driving ranges of up to 500 kilometers. This performance metric effectively elevates sodium-ion batteries. Consequently, they can realistically power a significant segment of the EV market, including daily commuters and family cars, without compromising on range.

Further pushing the boundaries, Zhaona New Energy recently revealed a solid-state sodium-ion battery prototype. This prototype features an astonishing energy density of 348.5 Wh per kilogram. This cutting-edge design utilizes a ceramic-coated structure and eliminates the anode, leading to improvements in both energy density and long-term stability. This breakthrough significantly narrows the performance gap between sodium-ion technology and high-end nickel manganese cobalt (NMC) lithium batteries, commonly found in premium EVs.

Advantages of Sodium-Ion EV Batteries: Cost, Safety, and Cold-Weather Performance

Beyond energy density, sodium-ion EV batteries offer several distinct advantages, making them particularly appealing for mass-market EVs. These benefits include lower manufacturing costs, superior cold-weather performance, and enhanced safety during transport and operation.

Cost-Effectiveness and Material Abundance

Sodium is an incredibly abundant element, readily available from sources like sea salt. Consequently, it is significantly less expensive than lithium. Furthermore, sodium-ion batteries avoid reliance on costly and geopolitically sensitive materials such as cobalt and nickel. The technology also eliminates the need for copper in current collectors, opting for aluminum instead, which further drives down production costs.

Analysts estimate that the cost of sodium-ion battery cells could drop to around $40 per kilowatt-hour. This is a substantial reduction compared to current LFP battery costs of approximately $70 per kilowatt-hour. This price point is crucial for enabling commercially viable EVs priced around $20,000 without government subsidies, thus making electric mobility accessible to a broader consumer base.

Superior Cold-Weather Performance

Cold-weather performance has historically been a significant drawback for lithium-ion batteries. In contrast, sodium-ion technology excels in this area. CATL’s Naxtra cells, for instance, retain about 90% of their capacity even at minus 40 degrees Celsius. This remarkable resilience makes sodium-ion batteries an ideal solution for EVs operating in colder climates, where lithium-ion batteries often experience significant range degradation.

Enhanced Safety and Zero-Voltage Tolerance

Safety is another critical aspect where sodium-ion batteries offer advantages. Unlike lithium-ion batteries, which require a minimum charge to prevent internal short circuits and can pose thermal runaway risks, sodium-ion batteries can be safely discharged to zero volts without damage. This zero-voltage tolerance greatly enhances safety during storage and shipping, simplifies logistics, and reduces the overall risk of incidents. Therefore, they are a safer choice for both manufacturers and consumers.

The Rise of Hybrid Battery Systems with Sodium-Ion Technology

While sodium-ion batteries present a strong case for many EV applications, they are not necessarily poised to replace lithium-ion entirely. Instead, the industry is increasingly exploring mixed-chemistry or hybrid battery systems. In these innovative configurations, sodium-ion cells can be strategically deployed to leverage their strengths, such as superior cold-weather performance, faster charge and discharge cycles, and lower cost. Meanwhile, lithium-ion cells continue to provide high energy density for applications demanding extended driving ranges.

This hybrid approach offers automakers unprecedented flexibility. They can fine-tune battery performance based on specific vehicle requirements, regional climatic conditions, and target market needs. For instance, an EV designed for urban commuting in a cold climate could benefit greatly from a sodium-ion dominant pack. Conversely, a long-haul electric truck might still rely on a substantial lithium-ion component. Although large-scale deployment of such mixed-chemistry systems is still in its early stages, research and development activity in this area is rapidly accelerating. This indicates a future where both technologies coexist to create optimized energy storage solutions.

Global Push for Scalability and Sustainable Battery Technology

The global manufacturing capacity for sodium-ion EV batteries is expanding at an exponential rate, with China leading the charge. Major players like CATL, BYD, and HiNa Battery are heavily investing in scaling up production to meet anticipated demand. BYD, for example, already has a facility in Qinghai actively producing sodium-ion cells specifically for entry-level electric vehicles, demonstrating a clear path to commercialization.

Beyond China, countries like India are also increasing their investments. Companies such as Reliance and KPIT are focusing on integrating sodium-ion technology into three-wheelers and light commercial vehicles, vital sectors for sustainable urban mobility. In Europe, France-based TIAMAT is concentrating on developing fast-charging sodium-ion cells. Furthermore, in the United States, companies like Natron Energy are pioneering grid-scale energy storage solutions using sodium-ion technology.

The widespread availability of sodium not only reduces geopolitical dependencies on lithium imports but also eliminates the need for cobalt and nickel mining, which are often associated with significant environmental and ethical concerns. Moreover, sodium-ion batteries are inherently easier and more cost-effective to recycle. This aligns perfectly with increasingly stringent sustainability standards in regions like Europe, promoting a circular economy for battery materials and advancing sustainable battery technology overall.

The Future of EV Batteries: A Diverse Ecosystem

While lithium-ion batteries are expected to maintain their dominance in high-performance applications, such as sports cars and long-haul trucks, where minimal weight and maximum energy density are paramount, the rapid ascent of sodium-ion EV batteries signifies a paradigm shift for the broader EV market. With their compelling combination of lower costs, improved safety, excellent cold-weather performance, and sustainable material sourcing, sodium-ion batteries are now positioned as a strong, serious, and compelling option for the majority of consumer electric vehicles.

This diversification of battery chemistries promises a more robust and resilient future for electric mobility. It also reduces reliance on single material supply chains and accelerates the global transition to sustainable transportation. The sudden emergence of sodium-ion batteries as a serious option is not just a technological achievement; it’s a testament to the continuous innovation driving the electric revolution.